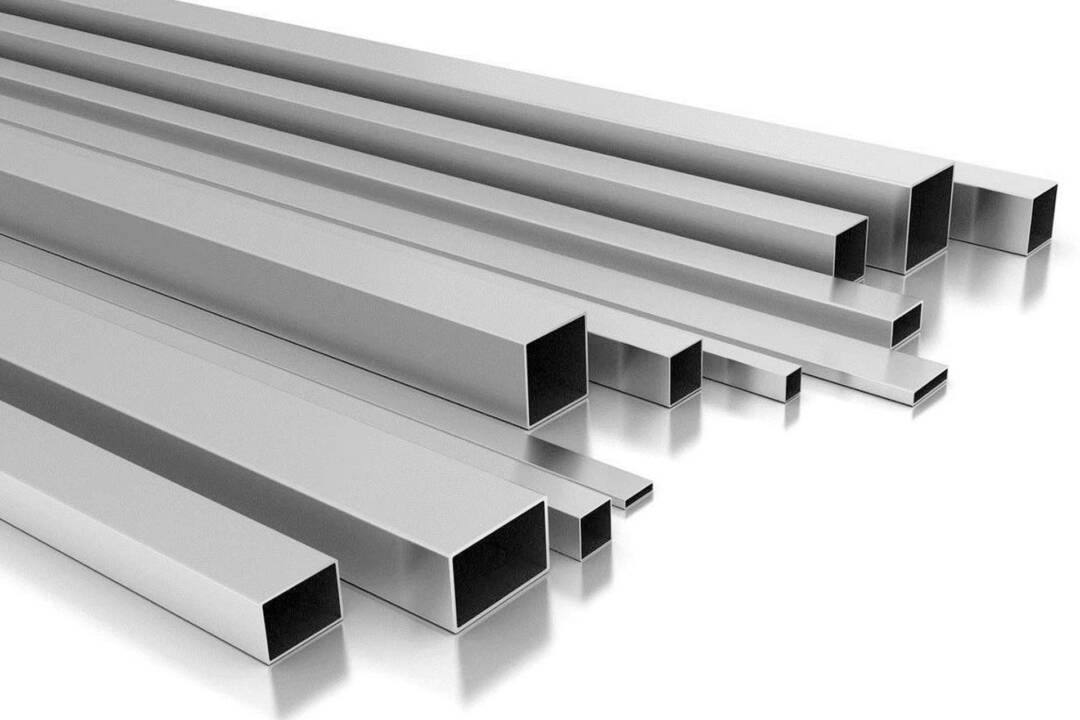

Aluminum Square Tubes in the Construction Industry

Aluminum square tubes are commonly used in the construction industry due to their strength, durability, and lightweight properties. They are used in various applications, including framework for doors, windows, and curtain walls. Additionally, aluminum square tubes are utilized in the construction of bridges, staircases, and other structural components.

One of the primary benefits of using aluminum square tubes in construction is their resistance to corrosion. This makes them ideal for use in outdoor environments, as they can withstand exposure to moisture, UV rays, and other harsh weather conditions without rusting or deteriorating. They are also fire-resistant, making them a safer option than other materials.

Another advantage of aluminum square tubes is their versatility. They can be easily customized to fit specific dimensions and requirements, and can be cut, welded, and bent to suit the needs of different construction projects. This makes them a popular choice for architects and designers who require flexibility in their design plans.

Overall, aluminum square tubes are an excellent choice for use in the construction industry due to their strength, durability, and versatility. They provide a cost-effective and reliable solution for a variety of structural applications and are an essential component in modern construction projects.

Aluminum Square Tubes in the Automotive Industry

Aluminum square tubes are an essential component in the automotive industry, where they are used in various applications due to their lightweight, high strength, and durability. They are commonly used in the construction of vehicle frames, suspension systems, and engine components, among other things.

One of the main benefits of using aluminum square tubes in the automotive industry is their weight. Compared to other materials such as steel, aluminum is significantly lighter, which can help to reduce the overall weight of the vehicle. This, in turn, can improve fuel efficiency and reduce emissions, making aluminum square tubes a more environmentally friendly option.

Another advantage of using aluminum square tubes in the automotive industry is their resistance to corrosion. This makes them ideal for use in vehicles that are exposed to harsh weather conditions, such as rain, snow, and salt on the roads. Additionally, aluminum square tubes can help to improve the overall durability and lifespan of the vehicle.

Overall, aluminum square tubes are an essential component in the automotive industry due to their lightweight, high strength, and durability. They provide a cost-effective and reliable solution for a variety of applications, and are an essential component in the production of modern vehicles.

The Role of Aluminum Square Tubes in Manufacturing

Aluminum square tubes are widely used in the manufacturing industry due to their versatility, strength, and durability. They are used in various applications, including the construction of machinery, equipment, and production lines.

One of the primary benefits of using aluminum square tubes in manufacturing is their strength. Aluminum is a highly durable material that can withstand heavy loads and extreme temperatures, making it ideal for use in the production of industrial equipment and machinery.

Another advantage of using aluminum square tubes in manufacturing is their versatility. They can be easily customized to fit specific dimensions and requirements, and can be cut, welded, and bent to suit the needs of different production processes. This makes them a popular choice for manufacturers who require flexibility in their manufacturing processes.

Overall, aluminum square tubes are an essential component in the manufacturing industry due to their versatility, strength, and durability. They provide a cost-effective and reliable solution for a variety of applications, and are an essential component in the production of modern machinery and equipment.