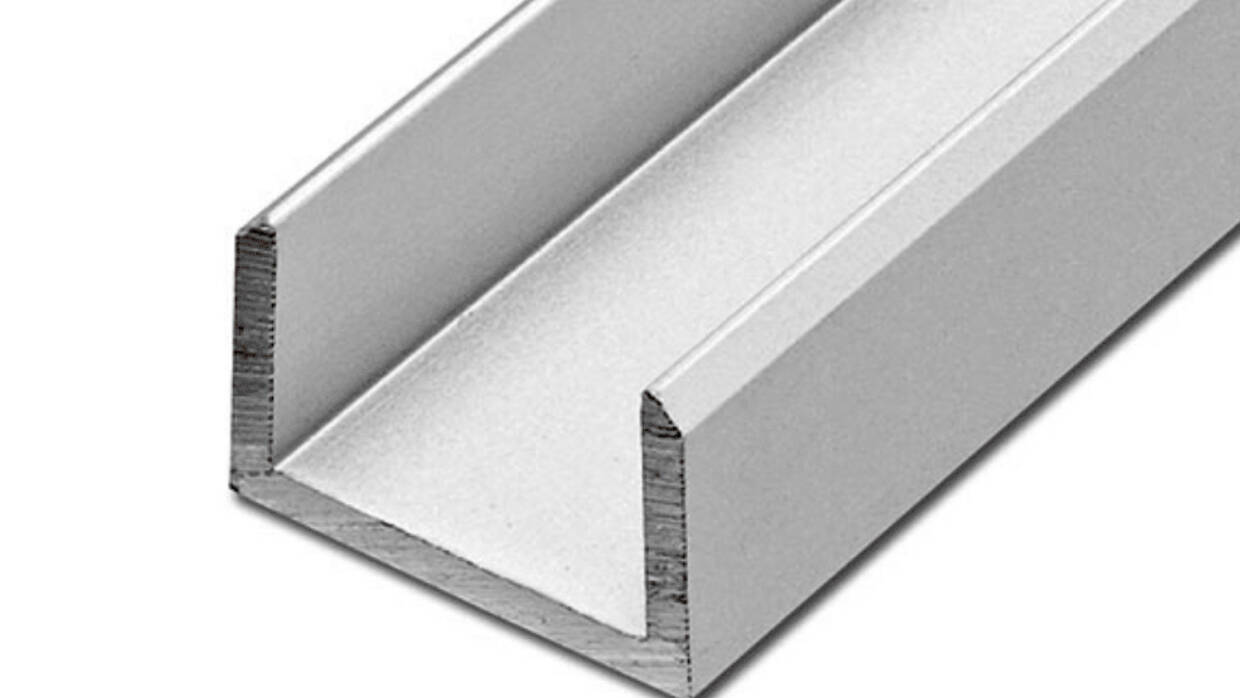

Aluminum radiused U tubes are a common component used in a wide variety of industrial and commercial applications. These tubes are designed to have a curved or rounded shape, which allows for the easy and efficient transfer of fluids or gases through a system. In this article, we will take a closer look at what aluminum radiused U tubes are, how they are used, and their advantages and disadvantages.

What are Aluminum Radiused U Tubes?

Aluminum radiused U tubes are simply U-shaped tubes made from aluminum. They are typically used in heating and cooling applications, where they allow for the transfer of fluids or gases between two different points in a system. The curved shape of the tube helps to reduce pressure drop and turbulence, making the flow of the fluid or gas much smoother and more efficient.

How are Aluminum Radiused U Tubes Used?

Aluminum radiused U tubes are used in a wide variety of industrial and commercial applications. Some common uses for these tubes include:

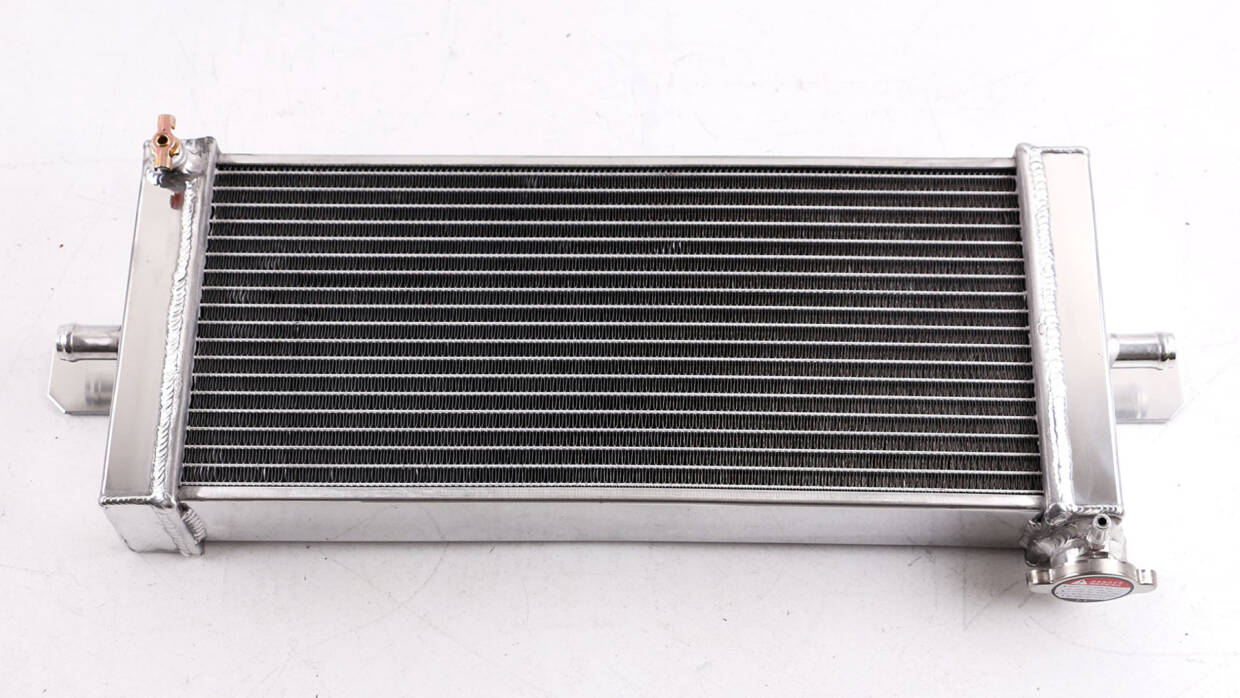

Heat Exchangers

Aluminum radiused U tubes are often used in heat exchangers, where they help to transfer heat between two different fluids. For example, they may be used in a water-cooled engine to transfer heat from the engine coolant to the outside air.

HVAC Systems

Aluminum radiused U tubes are also commonly used in HVAC (heating, ventilation, and air conditioning) systems. They may be used to transfer hot or cold air between different parts of the system, or to transfer heat between the air and a fluid, such as water.

Process Piping

Aluminum radiused U tubes are also used in process piping, where they help to transport fluids or gases between different parts of a system. They are often used in chemical plants and refineries, where they may transport corrosive or hazardous materials.

Advantages of Aluminum Radiused U Tubes

There are several advantages to using aluminum radiused U tubes in industrial and commercial applications. These include:

Efficient Fluid Transfer

The curved shape of the tube helps to reduce turbulence and pressure drop, making the transfer of fluids or gases much more efficient.

Corrosion Resistance

Aluminum is highly resistant to corrosion, which makes it an ideal material for use in harsh or corrosive environments.

Lightweight

Aluminum is a lightweight material, which makes it easy to handle and transport.

Easy to Fabricate

Aluminum is also easy to fabricate, which means that it can be easily formed into the curved shape required for radiused U tubes.

Disadvantages of Aluminum Radiused U Tubes

Despite their many advantages, there are also some disadvantages to using aluminum radiused U tubes. These include:

Cost

Aluminum is generally more expensive than other materials, which can make it less cost-effective in some applications.

Limited Temperature Range

Aluminum has a relatively low melting point, which means that it may not be suitable for use in applications where high temperatures are required.

Limited Strength

Aluminum is not as strong as some other materials, which may make it unsuitable for use in applications where high pressure or stress is present.

Conclusion

Aluminum radiused U tubes are a versatile and useful component used in a wide variety of industrial and commercial applications. They offer many advantages, including efficient fluid transfer, corrosion resistance, and ease of fabrication. However, they also have some disadvantages, including higher cost, limited temperature range, and limited strength. Overall, the decision to use aluminum radiused U tubes will depend on the specific application and requirements of the system.