Aluminum radiused rectangular tubes are a type of aluminum extrusion that has a curved or rounded edge on one or more sides. These tubes are made by a process known as extrusion, which involves heating a billet of aluminum and forcing it through a die to create a cross-sectional shape. The resulting extruded tube can be cut to a specific length and used in a wide variety of applications. In this article, we will explore the characteristics of aluminum radiused rectangular tubes and their usage area.

Characteristics of Aluminum Radiused Rectangular Tubes

Lightweight

One of the key characteristics of aluminum radiused rectangular tubes is their lightweight. Aluminum has a density of 2.7 g/cm³, which is only one-third the density of steel. This makes aluminum an ideal material for applications where weight is a critical factor, such as in the aerospace and automotive industries.

Corrosion-resistant

Aluminum is naturally corrosion-resistant due to the formation of a thin layer of oxide on its surface. This oxide layer acts as a protective barrier, preventing the aluminum from reacting with the environment. This makes aluminum radiused rectangular tubes an excellent choice for outdoor applications or those exposed to harsh environments.

Durable

Aluminum radiused rectangular tubes are highly durable due to their strength and resistance to corrosion. This makes them an ideal material for applications that require a long lifespan, such as building construction, transportation, and infrastructure.

Versatile

Aluminum radiused rectangular tubes are highly versatile due to their ability to be extruded into a wide variety of shapes and sizes. They can also be easily cut, drilled, welded, and machined to meet the specific needs of an application. This versatility makes them a popular choice for a wide range of industries.

- Cost-effective

Despite their many advantages, aluminum radiused rectangular tubes are also cost-effective. The cost of aluminum is lower than many other metals, and its lightweight nature also reduces shipping costs. Additionally, the durability and longevity of aluminum mean that it can provide long-term cost savings compared to other materials.

Applications of Aluminum Radiused Rectangular Tubes

Aerospace

The aerospace industry is one of the primary users of aluminum radiused rectangular tubes. The lightweight nature of aluminum makes it an ideal material for aircraft components, such as fuselage frames, wing ribs, and landing gear. Aluminum radiused rectangular tubes are also used in the construction of satellites, where weight is a critical factor.

Automotive

The automotive industry is another significant user of aluminum radiused rectangular tubes. The lightweight nature of aluminum makes it an ideal material for components that need to reduce weight, such as suspension systems, engine blocks, and body panels. Aluminum radiused rectangular tubes are also used in the construction of racing cars, where weight reduction is critical for performance.

Building Construction

Aluminum radiused rectangular tubes are used in building construction for a variety of applications. They can be used in the construction of curtain walls, storefronts, and windows. The lightweight nature of aluminum also makes it an ideal material for the construction of high-rise buildings, where weight reduction is critical for structural stability.

Infrastructure

Aluminum radiused rectangular tubes are also used in the construction of infrastructure projects such as bridges, tunnels, and railways. The lightweight nature of aluminum makes it an ideal material for these applications, as it reduces the overall weight of the structure and the load on the supporting pillars or walls.

Marine

Aluminum radiused rectangular tubes are used in the construction of boats and ships due to their corrosion-resistant properties. They are also used in the construction of offshore oil rigs, where the harsh marine environment can cause significant corrosion damage.

Sports Equipment

Aluminum radiused rectangular tubes are also used in the construction of sports equipment. For example, aluminum radiused rectangular tubes are commonly used in the construction of bicycles, golf clubs, and tennis rackets. The lightweight nature of aluminum helps to reduce the weight of the equipment, which can enhance performance.

Furniture

Aluminum radiused rectangular tubes are also used in the construction of furniture. The versatility of aluminum allows it to be easily shaped into a variety of forms, which can be used to create unique and modern furniture designs. The lightweight nature of aluminum also makes it easier to move and transport furniture.

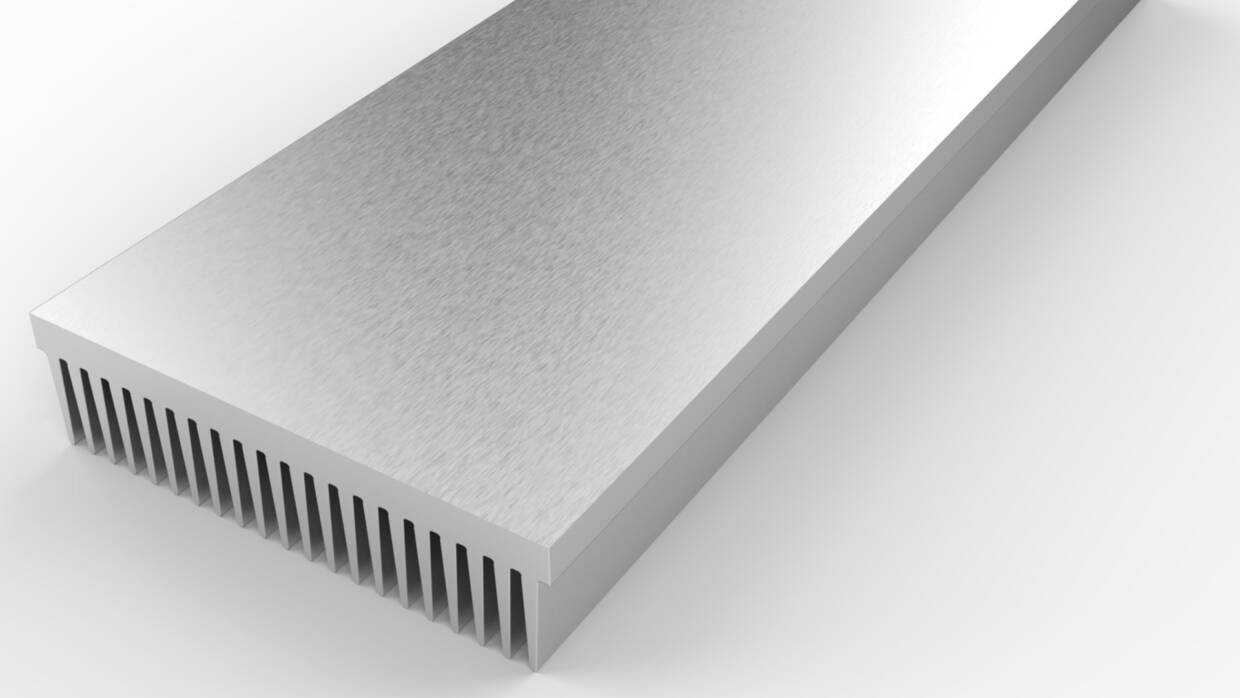

Electrical and Electronics

Aluminum radiused rectangular tubes are used in the electrical and electronics industry due to their excellent thermal and electrical conductivity. They are commonly used in the construction of heat sinks and electronic enclosures, which help to dissipate heat and protect electronic components.

Medical Equipment

Aluminum radiused rectangular tubes are also used in the construction of medical equipment. The lightweight nature of aluminum makes it easier to move and transport equipment, while its corrosion-resistant properties make it suitable for use in sterilization processes. Aluminum radiused rectangular tubes are commonly used in the construction of medical carts, hospital beds, and medical imaging equipment.

Conclusion

Aluminum radiused rectangular tubes are a versatile and cost-effective material that can be used in a wide range of applications. Their lightweight nature, durability, and corrosion-resistant properties make them an ideal choice for applications where weight reduction and longevity are critical factors. Aluminum radiused rectangular tubes are commonly used in the aerospace, automotive, building construction, infrastructure, marine, sports equipment, furniture, electrical and electronics, and medical equipment industries. With their many advantages, it is no surprise that aluminum radiused rectangular tubes are becoming an increasingly popular choice for manufacturers and engineers.