Aluminum rectangular tubes have been used in various industries for many years, and as technology advances, so too does the manufacturing of aluminum rectangular tubes. In this article, we will explore some of the recent advancements in aluminum rectangular tube technology, including the use of new alloys, extrusion techniques, and design innovations.

New Alloys for Aluminum Rectangular Tubes

Aluminum rectangular tubes are typically made from 6061-T6 or 6063-T5 aluminum alloy. However, there are many other alloys available that offer unique properties and benefits. Some of the new alloys that are being used for aluminum rectangular tubes include:

7000 series

The 7000 series of aluminum alloys offer high strength and excellent fatigue resistance, making them ideal for structural applications.

5000 series

The 5000 series of aluminum alloys offer high corrosion resistance and are often used in marine and other harsh environments.

2000 series

The 2000 series of aluminum alloys offer excellent heat resistance and are often used in aerospace and other high-temperature applications.

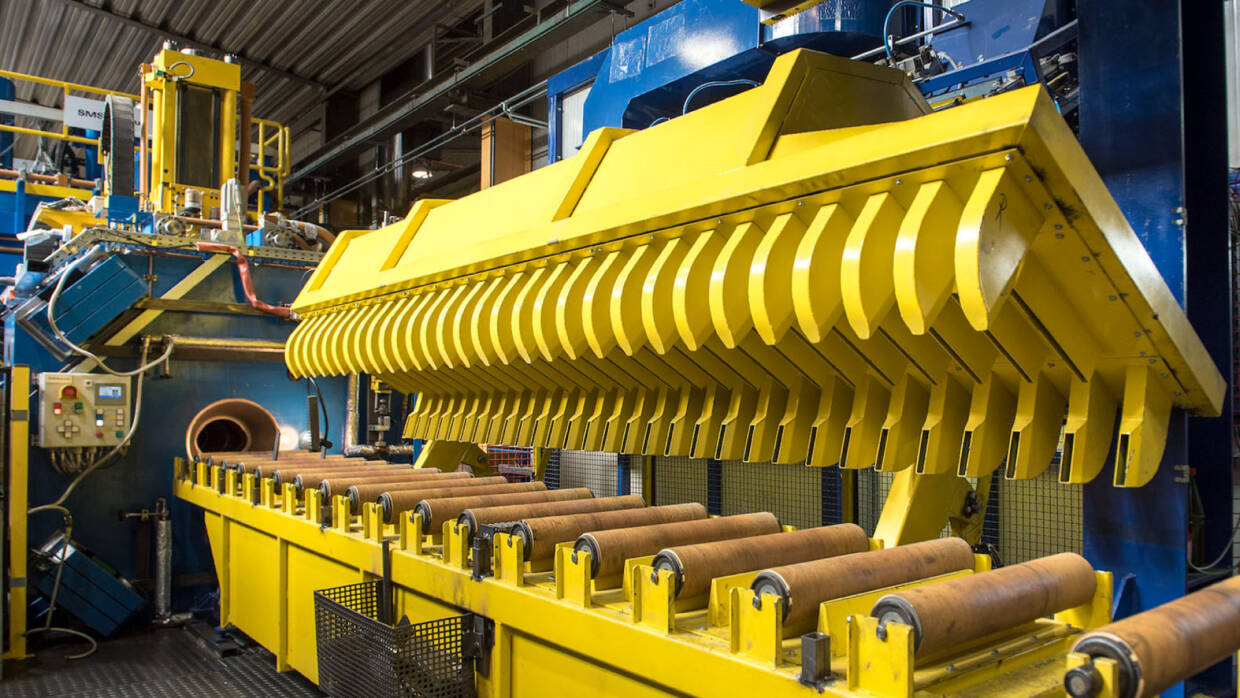

New Extrusion Techniques for Aluminum Rectangular Tubes

Extrusion is the most common method for producing aluminum rectangular tubes, but new extrusion techniques are being developed to enhance the process. Some of the new extrusion techniques for aluminum rectangular tubes include:

Hot extrusion

Hot extrusion involves heating the aluminum billet to a higher temperature than traditional extrusion methods, which allows for more complex shapes and tighter tolerances.

Hydroforming

Hydroforming involves using water pressure to shape the aluminum billet, which can create more intricate shapes and reduce the need for additional machining.

Design Innovations in Aluminum Rectangular Tubes

In addition to new alloys and extrusion techniques, there have been design innovations in aluminum rectangular tubes that are changing the way they are used in various industries. Some of the design innovations for aluminum rectangular tubes include:

Multi-chamber tubes

Multi-chamber aluminum rectangular tubes have been developed to provide added strength and rigidity. These tubes have internal walls that create multiple chambers, which distribute weight and stress more evenly.

Custom shapes

With advances in extrusion technology, aluminum rectangular tubes can now be extruded in custom shapes and sizes, allowing for greater design flexibility.

Improved strength and stiffness

Through the use of new alloys and extrusion techniques, aluminum rectangular tubes can now be manufactured with increased strength and stiffness, making them suitable for even more demanding applications.

Conclusion

Aluminum rectangular tubes continue to be an important material for a wide range of industries. As technology advances, new alloys, extrusion techniques, and design innovations are changing the way aluminum rectangular tubes are manufactured and used. With improved strength, durability, and flexibility, aluminum rectangular tubes are likely to remain a popular choice for many years to come.